5 Signs Your Factory is Ready for a Fully Automatic Biscuit Production Line

- Home

- 5 Signs Your Factory is Ready for a Fully Automatic Biscuit Production Line

Category: Industry Insights | Read Time: 7 Minutes

📋 Key Takeaways

- The CapEx Trap: While the initial investment is high, sticking to semi-manual processes often costs more in the long run due to excessive labor and material waste.

- Consistency is Currency: Automation guarantees identical weight, texture, and bake color for every biscuit—a non-negotiable requirement for securing supermarket contracts.

- The “Batch” Bottleneck: If your mixer is waiting for the oven, or your packaging team is waiting for cooling racks, your efficiency is bleeding money.

- Hygiene as a Selling Point: Fully automatic lines reduce human contact to near zero, simplifying compliance with international food safety standards (HACCP/ISO).

- Unlock Innovation: Manual methods struggle with complex products like center-filled cookies; automation enables high-margin product development at scale.

Introduction

There comes a point in every biscuit production factory’s life where the orders are flowing in, but the profit margins aren’t following. You’re working harder, adding shifts, and pushing your team to the limit, yet the output remains capped. It feels like you are running on a treadmill—moving fast but staying in the same place.

Moving from a manual or semi-automatic setup to a fully automatic biscuit production line is a massive leap. It represents a significant shift in capital, culture, and operations. It’s natural to hesitate. But often, the “safe” choice of sticking with what you know is actually the riskiest path of all.

This article isn’t about selling you a machine; it’s about helping you self-diagnose your operation. We will identify the 5 critical “breaking points” that indicate upgrading is no longer a luxury—it’s a survival necessity for your growing business.

Sign #1: Your “Rejection Rate” is Eating Your Profits

The Symptom: You are consistently throwing away 5-10% of your daily production. This waste comes from biscuits that are over-baked at the tray edges, under-baked in the center, or have irregular shapes that don’t fit the packaging.

The Technical Fix: In a fully automatic line, “guesswork” is replaced by PLC (Programmable Logic Controller) precision. The PLC synchronizes the speed of every component.

- Uniform Forming: The Rotary Moulder or Cutter is mechanically linked to the oven band speed. If the oven slows down, the moulder slows down instantly. This ensures the dough density and shape are identical for every unit.

- Consistent Baking: Unlike a rack oven where heat distribution can vary, a Tunnel Oven provides a consistent thermal profile. Every biscuit travels through the exact same heat zones for the exact same amount of time.

Commercial Value: Let’s do the math. If you produce 1,000kg of biscuits a day and waste just 5%, that’s 50kg of ingredients lost daily. Add the energy used to bake that waste and the labor used to make it. Over a year, that 5% waste could pay for a significant portion of a new line. Automation typically cuts rejection rates to under 1%.

Sign #2: You Can’t Land “Big Retail” Contracts

The Symptom: Large supermarket chains or national distributors are interested in your product, but negotiations stall. They require ISO/HACCP certifications that your current facility struggles to meet, or they demand volume guarantees (e.g., 5 tons/week) that your batch process cannot reliably deliver.

The Technical Fix:

- Contact-less Processing: A fully automatic line is a closed loop. Dough is tipped into the hopper and travels through forming, baking, cooling, and stacking without a single human hand touching it. This drastically reduces the risk of biological contamination.

- 24/7 Reliability: Batch ovens require downtime for loading and unloading. A continuous Tunnel Oven is designed to run non-stop for days or weeks. This predictability allows you to sign large contracts with confidence.

Commercial Value: Automation is a powerful marketing tool. Inviting a retail buyer to tour a fully automated, hygienic factory instills confidence. It proves you have the capacity and standards to be a low-risk, long-term partner.

Sign #3: Your Labor Costs Are Exceeding 25-30% of OpEx

The Symptom: Your factory floor is crowded. You are constantly hiring, training, and managing a large workforce just to move trays, load ovens, and pack biscuits. High turnover and absenteeism are constant headaches that disrupt production.

The Technical Fix:

- The Labor Shift: A semi-auto line might require 10-15 people per shift (mixing, forming, tray loading, oven loading, cooling, packaging). A fully automatic line transforms this structure. You might need only 3-4 skilled operators: 1 at the mixing station, 1 monitoring the oven/forming, and 2 managing the packaging outflow.

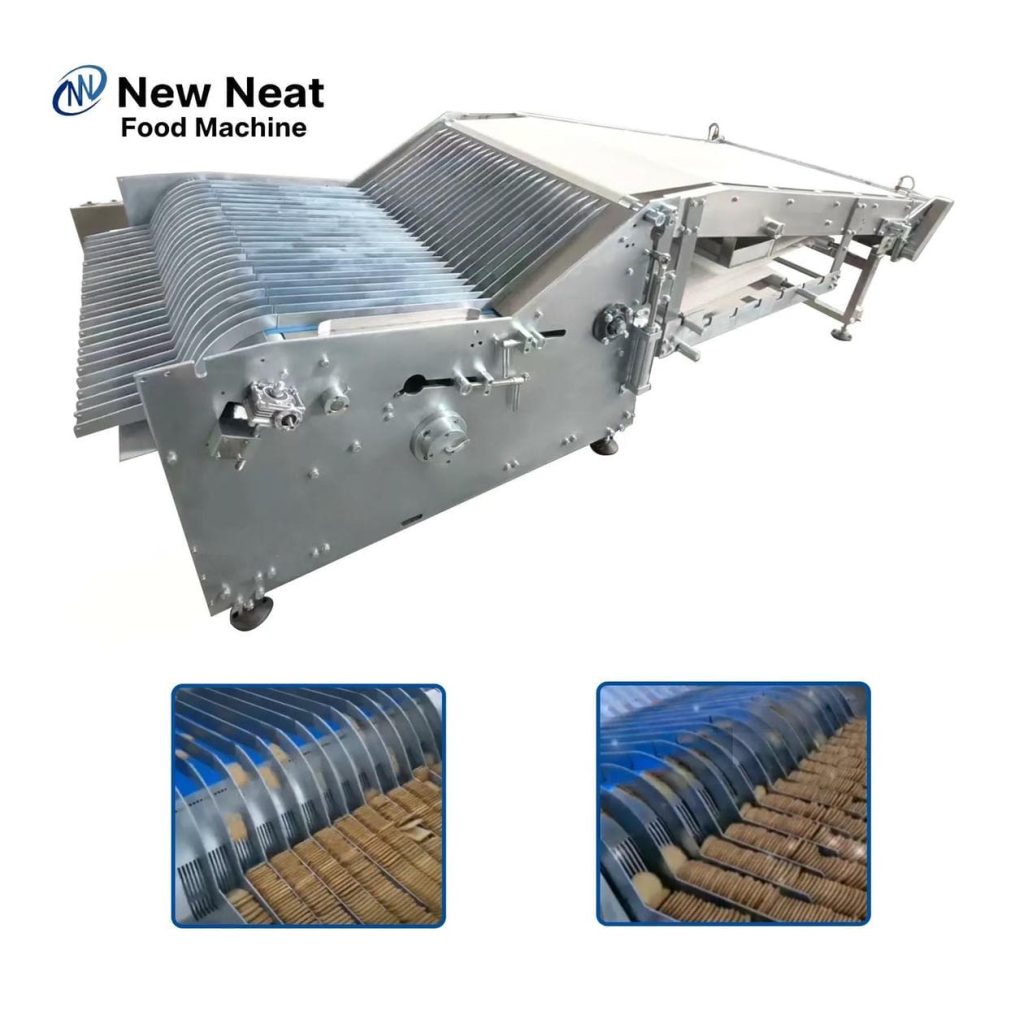

- Auto-Stacking: One of the most labor-intensive tasks is organizing baked biscuits for wrapping. An automatic Penny Stacker or Star Wheel Stacker does this at high speed, gently aligning biscuits into lanes for the flow wrapper, eliminating a major bottleneck.

Sign #4: The “Oven Bottleneck” is Slowing Down the Mixer

The Symptom: Walk onto your factory floor. Do you see the dough mixer sitting idle because the forming team can’t keep up? Or is the forming machine stopped because the batch oven is full? If your equipment is waiting, you are losing money.

The Technical Fix: The solution is Synchronization.

- Continuous Flow: In an automatic line, the belt never stops. As fast as you can mix and form, the oven can bake. There is no “waiting for the batch to finish.”

- VFD Control: Modern lines use Variable Frequency Drives (VFDs) on all motors. This allows you to speed up or slow down the entire line instantly from a central touchscreen. If the dough is slightly too wet and needs 10 more seconds in the oven, you slow the whole line down by 1% with a single tap, keeping the flow continuous.

Commercial Value: This is about Throughput Efficiency. You are maximizing the Return on Investment (ROI) for every square meter of your factory floor. An idle machine is an expensive piece of furniture; a running machine is a profit generator.

Sign #5: You Want to Innovate, but Your Equipment Says “No”

The Symptom: You see market trends shifting towards premium products—two-color biscuits, center-filled cookies with jam or chocolate, or intricate wire-cut shapes. You want to compete, but your current manual tools or simple moulders can’t produce these consistent enough to be profitable.

The Technical Fix: Automation unlocks Product Versatility.

- Advanced Forming: Automatic lines can integrate complex machines like Co-Extruders (for filled cookies) or Wire-Cut machines (for cookies with inclusions like chocolate chips).

- Precision Injection: These machines can inject fillings with millimeter precision at high speeds, ensuring every cookie has the perfect “bite”—something virtually impossible to achieve consistently by hand.

Commercial Value: Product differentiation allows for premium pricing. Complex, high-quality products (like filled cookies) command much higher profit margins than simple, commodity biscuits. Automation gives you the capability to enter these higher-value markets.

The “Reality Check”: Pre-requisites for Automation

If you identified with the signs above, your business is ready for automation. But is your facility ready? Before requesting a quote, check these basics:

- Space: Automatic lines are linear and long. A typical line can range from 40 meters to 100 meters in length. Do you have the physical length, or can you knock down a wall?

- Power & Utilities: Do you have the electrical infrastructure (kW capacity) to run heavy-duty motors and heating elements? If choosing a gas oven, is your gas supply sufficient and stable?

- Technical Mindset: You won’t need more staff, but you will need different staff. You will need operators who can manage a touchscreen and technicians who can grease bearings, rather than manual laborers moving trays.

FAQ: Overcoming the Fear of Upgrade

1. Will I have to shut down production to install the new line? Installation is a major operation, typically taking 2-4 weeks depending on complexity. Smart factory owners plan this during their low season or build up a “stockpile inventory” to cover orders during the transition. The short-term downtime is a small price for the long-term efficiency gain.

2. What is the typical ROI period for a fully automatic line? While it varies, most factories see a full return on investment in 18 to 36 months. This calculation includes savings from reduced labor, lower waste (rejection rate), and the profit from increased production capacity.

3. Is it hard to switch from one product to another (Changeover time)? It used to be, but not anymore. Modern lines use “Quick Change” parts (like moulder dies) that can be swapped without tools. Combined with the PLC’s “Recipe Memory” (which auto-sets speeds and temperatures), a full product changeover can often be done in minutes, not hours.

4. Can I keep my old mixers? Often, yes! The “automatic line” typically starts after the mixing stage. You can continue using your batch mixers. We simply install a Dough Tipper or Feeding Conveyor to automate the transfer of dough from your mixer bowls into the line’s forming machine.

Conclusion

If you are fighting daily battles with product inconsistency, rising labor costs, and capacity ceilings, manual production is no longer the “cheap” option—it is the most expensive way to operate.

Automation allows you to stop working in your business (moving trays and fixing mistakes) and start working on your business (expanding into new markets and developing new products).

Does your factory show these 5 signs? Don’t let inefficiency hold you back. Request a free factory layout consultation today, and let’s visualize how a fully automatic biscuit production line fits into your future.