Hard Biscuit Production Line vs. Soft Biscuit Production Line: Which Configuration Fits Your Factory?

- Home

- Hard Biscuit Production Line vs. Soft Biscuit Production Line: Which Configuration Fits Your Factory?

Category: Food Processing Machinery | Read Time: 8 Minutes

Key Takeaways

- Dough Physics Dictates Machinery: Hard dough (crackers) requires lamination and stress relief; soft dough (cookies) requires gentle molding without gluten development.

- Factory Footprint: Hard biscuit lines are significantly longer (often 100m+) due to the lamination and gauge roll sections; soft lines are compact.

- Yield & Waste: Soft lines offer nearly 100% immediate yield. Hard lines produce scrap webbing that must be recycled via a return conveyor system.

- Commercial Viability: Soft lines have lower startup costs (CapEx) and are easier to operate. Hard lines produce high-volume staples with longer shelf stability.

- The “Hybrid” Option: A Combination Line offers versatility but requires higher investment and a larger facility.

Introduction

The global biscuit market is resilient and expanding. With current projections valuing the market at over $120 billion and growing steadily, the opportunity for manufacturers is clear. However, in an industry where margins are dictated by volume and efficiency, the profitability of your factory doesn’t just depend on your recipe—it depends on your machinery configuration.

For new factory owners and procurement officers, a common pitfall is underestimating the drastic technical differences between processing “Soda Crackers” (Hard Dough) and “Shortbread Cookies” (Soft Dough).

Buying a generic “biscuit line” is a recipe for inefficiency. If you attempt to run soft, high-fat dough through a hard biscuit laminator, you face oil separation and clogging. Conversely, forcing elastic hard dough into a rotary moulder results in biscuits that shrink, warp, and lack that characteristic “snap.”

This guide compares the two primary configurations of industrial biscuit production lines. We will analyze the machinery components, space requirements, and operational costs to help you make an informed purchasing decision that maximizes your ROI.

The Science Behind the Machine: Understanding Dough Rheology

Before looking at the steel, you must look at the dough. The configuration of your production line is ultimately dictated by the Fat-to-Sugar-to-Water ratio.

1. Hard Dough (The “Elastic” Network)

- Examples: Soda crackers, Marie biscuits, Petit Beurre.

- Characteristics: Low fat, high water content. The mixing process is designed to develop a strong gluten network. This dough is elastic and “springy.”

- Machine Requirement: Because the dough is elastic, it shrinks if molded immediately. It requires work (energy)—stretching, folding, and relaxing—to create the layered, flaky texture consumers expect.

2. Soft Dough (The “Short” Texture)

- Examples: Shortbread, Glucose biscuits, Chocolate Chip cookies.

- Characteristics: High fat and sugar, low water. Mixing is minimal to inhibit gluten formation. The dough is crumbly or “short.”

- Machine Requirement: This dough has no elasticity. It cannot be stretched or sheeted without tearing. It requires gentle compression to take shape.

The Bottom Line: Because the dough behaves differently, the forming machinery must act differently.

Deep Dive: The Hard Biscuit Production Line Configuration

The Hard Biscuit Line is characterized by its length and complexity. The goal of this line is to reduce a thick mass of dough into a thin, multi-layered sheet without stressing the gluten so much that the biscuit deforms in the oven.

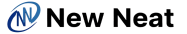

The Forming Section Breakdown

- The Laminator: This is the most distinct feature. Whether using a Vertical or Horizontal Laminator, this machine takes dough sheets and folds them over one another. This creates the internal layers that give crackers their flaky texture.

- Gauge Rolls (Reduction Stations): You cannot reduce dough thickness in one step. A hard line typically employs a series of 3 to 4 Gauge Roll units. Each unit gently reduces the sheet thickness (e.g., from 10mm to 5mm to 2mm) to preserve the dough’s integrity.

- Relaxation Web: Between gauge rolls, the conveyor often runs slightly slower or forms waves to allow the gluten to “relax,” preventing oval-shaped biscuits.

- Rotary Cutter: Unlike soft biscuits, hard biscuits are cut from a continuous sheet. A dual-roll system cuts the shape and stamps the pinholes (docker holes) which allow steam to escape during baking.

- Scrap Return System: Since you are cutting circles or squares out of a sheet, you are left with “scrap webbing.” A crucial component of this line is the Side Scrap Return Conveyor, which lifts the excess dough and returns it to the hopper for re-sheeting.

Deep Dive: The Soft Biscuit Production Line Configuration

The Soft Biscuit Line focuses on compactness and speed. Since there is no gluten network to manage, the machinery is far simpler.

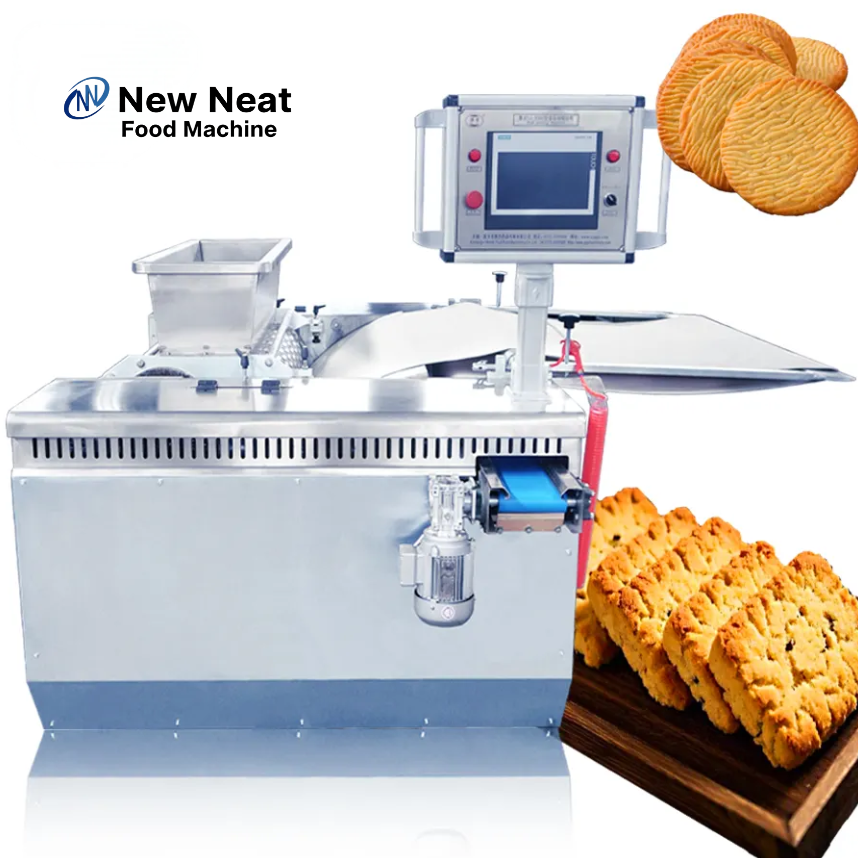

The Heart of the Line: The Rotary Moulder

The soft biscuit line skips the lamination and gauge roll sections entirely. Instead, the dough is dumped directly into the hopper of a Rotary Moulder.

- How it works: A forcing roll pushes the crumbly dough into engraved cavities on a die roll. A scraping blade removes excess dough, and a rubber extraction belt pulls the formed biscuit out of the die and places it onto the oven band.

- No Lamination: By removing the laminator and gauge rolls, you save approximately 10–15 meters of factory floor space.

- Zero Waste: Because the dough is molded individually rather than cut from a sheet, there is no scrap webbing. 100% of the dough on the belt goes into the oven, resulting in higher immediate yield and eliminating the need for complex recycling conveyors.

Commercial Comparison: ROI, Space, and Operational Costs

For the factory owner, technical specs translate directly to the balance sheet. Here is how the two lines compare commercially.

1. Factory Footprint

- Hard Line: Requires a long factory hall. A standard industrial line can easily exceed 60m–100m in length depending on the required oven time.

- Soft Line: Highly compact. Suitable for facilities with limited length. A high-capacity soft line can often fit in 60% of the space required for a hard line.

2. Energy Consumption

- Baking Profile: Hard biscuits (crackers) generally require longer baking times to dry out moisture content to below 3%.

- Soft Biscuits: High sugar/fat content allows for faster baking.

- Result: Hard lines typically have higher utility costs (gas/electricity) per kilogram of finished product compared to soft lines.

3. Maintenance & Complexity (OpEx)

- Hard Line: More moving parts (laminators, multiple gauge rolls, scrap return systems) equals a more rigorous maintenance schedule. It also requires skilled operators who understand how to adjust gauge roll speeds to prevent dough tearing.

- Soft Line: The Rotary Moulder is a “set and forget” machine. Once the pressure is set, the operation is straightforward. This lowers your Operating Expenditure (OpEx) regarding labor and spare parts.

4. The “Hybrid” Solution (Combination Line)

Can’t decide? Many manufacturers opt for a Combination Line. This “All-in-One” solution installs a Rotary Moulder inline with the Laminator and Cutter. By lifting or lowering conveyors, you can bypass the hard section to run soft biscuits, and vice versa.

- Pros: Maximum market flexibility.

- Cons: Highest initial Capital Expenditure (CapEx).

The Baking & Post-Baking Stages

While the forming sections differ, the backend of the line shares similarities, with key nuances.

Tunnel Oven Zones

- Hard Biscuits: Often utilize Direct Gas Fired (DGF) ovens in the first zone. The intense, direct heat provides the “oven spring” (lift) needed for crackers.

- Soft Biscuits: Often prefer Cyclotherm or Convection heating to ensure even coloring and setting of structure without excessive spreading.

- Belt Type: Hard biscuits usually bake on a wire mesh band to allow airflow and crispiness. Soft biscuits often require a solid steel band to retain their high fat content and shape.

Cooling & Stacking

- Cooling Conveyors: Do not skimp here. Biscuits leave the oven at over 100°C. If packaged too hot, condensation forms inside the wrapper, leading to mold. A general rule of thumb is a cooling conveyor length 1.5x the length of the oven.

- Stacking:

- Penny Stackers are used for high-speed, durable hard biscuits.

- Star Wheel Stackers provide gentler handling for fragile soft cookies.

FAQ: Common Buyer Questions

Q: Can I produce both hard and soft biscuits on the same production line? A: Yes, but you cannot do it with a standard line. You need a “Combination Line” (or Hybrid Line). This line includes both the Laminator/Cutter unit and a Rotary Moulder unit. While versatile, it increases the line length and initial investment cost.

Q: What is the minimum capacity for an industrial biscuit production line? A: While entry-level artisan lines exist, profitable industrial lines typically start at 100kg/hr. However, for a viable ROI in a competitive market, most factories install lines running between 500kg/hr to 1500kg/hr.

Q: Which line requires more labor to operate? A: The Hard Biscuit Line typically requires more skilled operators. Managing the lamination layers, synchronizing the gauge roll speeds, and monitoring the scrap return requires active supervision. Soft lines are generally more automated and easier to run.

Q: Can I make “Centre-Filled” cookies on these lines? A: Standard soft lines produce solid cookies. To make centre-filled (jam or chocolate filled) cookies, you need an additional machine called an Encrusting Machine or a specialized dual-hopper Rotary Moulder.

Conclusion

Choosing between a Hard and Soft Biscuit Production Line is not just a preference—it is a strategic business decision rooted in your target market.

- Choose a Hard Line if: You aim to produce high-volume staples like crackers and Marie biscuits with long shelf lives, and you have the factory space to accommodate the lamination equipment.

- Choose a Soft Line if: You are targeting the “indulgence” market with cookies, have limited factory space, or want a lower entry barrier with easier operation.

Still unsure which configuration fits your business model? Don’t guess with your capital. Contact our engineering team today. We can simulate your production capacity and layout a custom floor plan that fits your facility and your budget.